| Hot Coiling Facilities |

| |

| * Click on image for enlarge. |

| |

|

Our hot coiling plant of 19,800 sft has state-of-art coiling machine, Heat Treatment facilities and various load testing machines supported by semi-auto-production line and other advanced facilities resulting in complete and safe springs rolled out. |

|

| |

|

| |

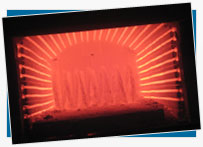

Our Numerical controlled fully automatic spring coiling machine coils springs in hot coiling process with automatic pitching and end closing upto 50.0 mm rod diameter. Our 33 feet long oil fired furnace have control of preheating the bars with accurate temperature of ± 10ºC and allows us to make springs with large wire/rod lengths. |

|

|

| |

|

| |

|

Controlled heat-treating in batches at temperatures up to 1,000 degrees Centigrade enables us to provide extremely consistent and uniform products. VCI Springs will provide heat chart trace ability upon request.

Heat Treatment involves hardening the spring by means of heating it to a required temperature and quenching it in a mineral based quenching oil. |

|

| |

The spring is then tempered by re-heating to a pre-determined temperature and held for set period to achieve the required mechanical properties. The heat treated spring then posses properties that will guarantee its service life and enhance its safety. |

| |

|

| |

Heat treatment of all our springs are done by accurately controlled processes to produce a finished material hardness within recognised specifications.

Our Heat treatment furnaces and high temperature ovens enable us to have complete control over the stress relieving and heat treatment requirements of springs. Heat treatment of all our springs is done by accurately controlled processes to produce a finished material hardness within recognised specifications. |

|

|

| |

We also have fully automatic conveyorised oil quenching tank with a length of 22 feet which controls us to produce springs without bend and less safety gap in springs and is of 10,000 litres capacity. |

| |

|

| |

|

Our automatic grinding machines for spring end grinding can grind springs of wire dia upto 50.0 mm. This grinding machine is capable to grind any size spring and can give accurate grinding finish to springs achieving parallelity and perpendicularity (Squareness). We also have in-house end tapering facilities for hot coiled springs. |

|

| |

|

| |

VCISprings has the expertise to manufacture high stress springs, which involves the process of shot peening. A rotary barrel type shot peening machine has been recently installed. Shot peening (surface strengthening) extends the durability of springs. Shots are propelled on the rotating coil springs at high velocity thereby peening it.

Hot coiled springs finish our coil springs are powder coated as per buyer's color choice, as well as we provide painted springs as per requirement. |

|

|

| |